- Home

- Boating

Express Shipping Available

We use Australia Post and Toll*.

Buyer Support

Get in touch 24/7

Total Security

Secure checkout

RETURN POLICY

30 Days.

- Fishing

Express Shipping AVAILABLE

We ship with Australia Post and Toll*.Buyer Support

Get in touch 24/7Total Security

Secure checkoutRETURN POLICY

30 Days. - RV Parts and Accessories

- Boat Maintenance

Express Shipping AVAILABLE

We ship with Australia Post and Toll*.Buyer Support

Get in touch 24/7Total Security

Secure checkoutRETURN POLICY

30 Days. - Wishlist

Browse Categories - Menu

- Anchoring & Docking

Boat Anchoring & Docking When it comes to boating, anchoring and docking are essential aspects of safety and security. One might think that it’s just a matter of throwing an anchor overboard and being done with it, but there is much more to anchoring and docking than meets the eye. Boat Anchoring ensures that your boat stays in place and doesn’t drift away, and properly docking is paramount for the safety of your boat and other boats around you. Read More Given the importance of boat anchoring and docking, we offer a wide range of boat docking products, along with our high-quality boat anchors, to keep your boat safe and secure in port. Our selection includes dock lines, fenders, and bumpers, which are important for protecting your boat from damage while docked. Not all boat anchors are created equal. It’s important to choose the right anchor for your boat’s type, size, and weight. Our wide range of boat anchors suits different types of boats and different water conditions. Our lightweight, fluke-style anchors are perfect for smaller boats and calmer waters, while our heavier, plough-style anchors are ideal for larger boats and rougher seas. We…

- Boat Anchors

- Fenders

- Sand Anchors

Sand Anchors If you’re looking for a reliable and efficient way to anchor your boat on sandy beaches, sand anchors are a must-have accessory. Sand anchors are designed to work in soft sand, making them a perfect solution for boaters who enjoy spending time on beaches or in shallow waters. Read More Our boat and marine accessories website offers a range of sand anchors to suit different types of boats and preferences. Our sand anchors are made from high-quality materials that are durable and corrosion-resistant, ensuring that they last for many years of use. They are also lightweight and easy to store, making them convenient for boaters who travel light. Our sand anchors come in various sizes and designs, including screw-type and fluke-type anchors. Screw-type sand anchors are designed to twist into the sand, providing a firm grip and holding power. Fluke-type sand anchors, on the other hand, are designed to dig into the sand and create a suction effect, providing excellent holding power in soft sand. Sand anchors are particularly useful for boaters who like to spend time on secluded beaches or shallow waters, where traditional anchors may need improvement. With our sand…

- Winches & Windlasses

Muir Winches & Windlasses Muir Windlasses Australia specialises in the manufacture of high-quality, Australian-made windlasses and anchoring systems that stand the test of time. They equip vessels from five metres to 150 metres and have the most extensive range of anchor windlasses and equipment available on the world market. From pleasure craft and superyachts, to a spread of commercial vessels, Muir’s range is comprehensive and known for its superior technology. Muir products are exported to more than 50 countries worldwide from our Tasmanian head office, manufacturing and design facilities. Muir also holds warehousing and sales facilities in Sydney, the Gold Coast, Florida USA, and Southampton UK, together with a very strong distribution network which covers the rest of the globe. Muir has firmly established itself as a market leader in the design and manufacture of its products both within Australia and overseas, and is renowned for its high-quality, performance and reliability. With nearly half a century of combined experience in anchor windlass technology, Muir technicians and engineers have designed and developed a superior range of pleasure craft windlasses and products that meet the requirements of the most discerning clients and their vessels. https://www.muir.com.au/ We have access to the Muir range…

- Biminis & Rocket Launchers

Biminis, Boat Covers & Rocket Launchers Boat Hut offers a number of Bimini, T-Tops, Boat Covers and Rocket launchers. All that is necessary to determine which size top to order is choosing the length, height and width that best accommodates your boat and your requirements Using a tape measure, decide which length top covers the portion of the boat you want covered, i.e. 1650mm or 2400mm. The pivotal mounting point will be approximately at the centre point of the top of each side of the boat. The deck mounts included with the top are designed to mount on a relatively flat horizontal surface. Side mounts are supplied with this product. After determining where the pivotal mount location will be on each side of the boat, measure the distance between these mounting points to determine the width of top you need. While standing inside the boat, measure from the pivotal mounting point straight up to determine desired height. Once you have all the measurements, simply go to the sizing chart on this box and select the one you need. All of the instructions are supplied in the box.

- Boat Covers

Boat Covers Protect your vessel with our premium range of Boat Covers available at Boat Hut. Crafted with high-density material, our boat covers ensure long-lasting defence against the elements, prolonging your boat’s lifespan and maintaining its aesthetic appeal. Read More Boat covers are not only a practical solution to keeping your boat protected, but they also offer added benefits that any boat owner should consider like: * Protection Against Wind – Boat covers serve as a crucial line of defence against wind during travel, preventing belongings from being scattered or blown out of the boat. Wind can be relentless and unpredictable, and a well-fitted boat cover can effectively secure any loose items or protruding elements under its protective shield. This includes fishing gear, cushions, life vests, and other essential equipment, ensuring safe and hassle-free boating experiences. * Protection from harsh weather conditions – Your boat is constantly exposed to the sun, wind, rain, and snow. Boat covers act as a barrier against these elements, keeping your boat clean and protected from potential damage. Prevention of water buildup – When your boat is not in use, it can easily accumulate water on its surface, causing…

- Canopy Fittings

Canopy Fittings Canopy fittings are an essential accessory for boaters who want to enjoy their time on the water while staying protected from the sun and rain. At Boat Hut, we offer a wide range of canopy fittings to suit different types of boats and preferences. Read More Crafted from premium-grade materials that are built to last and withstand the unforgiving marine environment, our canopy fittings are available in various sizes and designs, including straight and angled fittings. Installing them is a breeze with just basic tools. We offer a range of canopy fittings to suit different boats, including sailboats, powerboats, and pontoon boats. Our fittings are designed to provide a secure and stable frame for your canopy, ensuring it stays in place even in windy conditions. In addition to our range of canopy fittings, we also offer a variety of accessories to enhance your boating experience. These include canopy fabric, tubing, and hardware. Our canopy fabric is available in different colours and materials, including Sunbrella® and marine-grade vinyl, to match your boat’s style and provide maximum UV protection. Our tubing is available in various lengths and diameters to suit different canopy sizes, and…

- Chemicals

- Silicone Grease

Silicone Grease If you’re a boater, RV owner, or marine enthusiast, silicone grease is an indispensable accessory. That’s why we offer a selection of top-quality silicone greases at Boat Hut to meet all your lubrication needs. Our silicone greases are designed with the unforgiving marine environment in mind, ensuring that they offer long-lasting lubrication and safeguard against rust and corrosion. With a variety of viscosities available, our silicone greases can be applied on multiple surfaces, including rubber, plastic, metal, and electrical components. Our silicone greases are also safe to use on rubber seals, gaskets, and O-rings, making them a versatile lubricant for your boat, RV, or marine equipment. They are also compatible with most plastics and metals, ensuring that you can use them on a wide range of surfaces without causing damage. In addition to their lubrication properties, our silicone greases also provide excellent water resistance, making them ideal for use in wet or humid conditions. They can also withstand high temperatures, ensuring that they remain effective even in extreme weather conditions. At Boat Hut, we take pride in providing high-quality products at affordable prices. Our silicone greases are no exception, and we are confident that they will meet and…

- Controls

- Control Cables

Control Cables We carry the leading brands of control cable – Seastar, Vetus, Ultraflex and Multiflex. Seastar What to consider when selecting cables SeaStar Solutions® makes engine control cables for a wide variety of applications. They recommend their use with SeaStar Solutions® controls as well as in engine manufacturers’ control systems. Cables are available in three grades Read More Standard cables are suitable for most applications with short, simple cable routings. Mid-range cables are recommended for somewhat longer cable routings and heavier use than their standard counterparts. For difficult cable routings or anywhere uncompromising performance is needed, use Premium (XTREME™) control cables. OEM Replacement Type These throttle/shift control cables are direct replacements for applications using engine makers’ controls with proprietary cable interfaces, such as: Evinrude®, Johnson®, Mariner®, MerCruiser®, Mercury®, Force® and some Volvo® engines. Most other engine makers use universal type cables (10-32 UNF threaded ends) and connection kits. Universal 3300/33C Series Universal 30/33 series throttle/shift control cables are direct replacements for many boats using aftermarket controls or the following engine makers controls: Yamaha®, Honda®, Suzuki®, Tohatsu®, Volvo®, BMW®, Chrysler® and others. These are offered in five versions: one standard, two midrange and two…

- Electrical

- Bulbs

Bulbs If you’re looking for reliable and high-quality electrical bulbs for your boat, RV, or marine equipment, look no further than Boat Hut. We offer a wide selection of electrical bulbs that are specifically designed to withstand the harsh marine environment, ensuring long-lasting performance and efficiency. Read MoreOur electrical bulbs come in various types and sizes, including LED and halogen bulbs. LED bulbs are energy-efficient, providing bright light while consuming minimal power. Halogen bulbs are known for their high luminosity and excellent colour rendering, making them a popular choice for marine lighting. All our electrical bulbs are made from high-quality materials that are resistant to the saltwater, moisture, and vibration that can damage bulbs in the marine environment. They are also designed to withstand the extreme temperatures and weather conditions that are common on boats and RVs. We take pride in providing our customers with high-quality products at affordable prices. That’s why we offer a wide selection of electrical bulbs at competitive prices. Whether you need to replace a single bulb or upgrade your entire lighting system, we have the right bulbs for your needs.

- Fishfinders

- Instruments & Gauges

Instruments & Gauges If you’re a boater or RV owner, you know how crucial it is to have reliable and accurate instruments and gauges to monitor your vehicle’s performance. At Boat Hut we offer a range of top-quality instruments and gauges from reputable brands like KUS and Veethree Instruments. Read More Our KUS Trim Gauge is designed to provide you with accurate and reliable information about your boat’s trim position, allowing you to adjust it for optimal performance and fuel efficiency. It features a clear and easy-to-read display and is compatible with most types of boats. Our Veethree Instruments are designed to provide you with reliable and precise readings of your vehicle’s vital signs, including speed, RPM, oil pressure, and water temperature. They are available in a variety of designs and sizes to suit different types of boats and RVs. Our KUS Fuel Gauge is essential for monitoring your fuel levels and ensuring that you have enough fuel to reach your destination. It features a clear and easy-to-read display and is compatible with most types of boats. Our instruments and gauges are constructed using top-tier materials that are built to withstand the challenging marine…

- Mastervolt

Mastervolt Discover our wide range of Mastervolt battery chargers, inverters, Combis, DC-DC converters and batteries. Boat Hut has access to the Mastervolt range and can order in any of their products to meet you needs. Read More Mastervolt Battery Chargers – Mass A long life for your battery! Do you want to charge your batteries safely, reliably, and preferably quickly, even when you are in a marina with poor shore power or a limited power supply? Do you also value batteries that have a long lifespan while maintaining their capacity? Mastervolt offers you the best possible solution. The Mastervolt 3-step charging method ensures more power and a longer life for your batteries. Our battery chargers integrate multiple functions, charging your battery safely and completely even when they are depleted. Fast battery charging is guaranteed by the efficient use of the available shore or generator power (all Mastervolt battery chargers have a power factor correction). Mastervolt is Green by Heart. Which battery charger best meets your needs? We offer three types of battery chargers: Charge Pro™: Range of waterproof battery chargers for recreational use and sport fisherman. Multiple outputs allow for flexibility. ChargeMaster: Suitable for…

- Switches & Fuses

Switches & Fuses If you’re a boater or RV owner, you know the importance of having reliable and efficient switches and fuses to control your electrical systems. At Boat Hut, we offer a wide range of high-quality switches and fuses from reputable brands like Blue Seas, BEP, and more. Read More Our Rule-A-Matic Float Switch is a must-have accessory for any boat owner. It automatically controls your bilge pump, ensuring that your boat stays dry and safe. It is easy to install and features a reliable and durable design that will last for years. Our Switch Panel with 8 Switches & Circuit Breakers is a convenient and easy-to-use accessory for controlling multiple electrical systems on your boat or RV. It features a compact design and is easy to install, with clear instructions and all necessary hardware included. Our BEP Insulated Dual Power Studs are perfect for connecting multiple electrical components on your boat or RV. Crafted from premium-quality materials, our switches and fuses can withstand the challenging marine environment, providing consistent and dependable performance. Our Deck Foot Switch For Anchor is a convenient accessory that allows you to control your boat’s anchor from the…

- Fishing Accessories

Fishing Accessories At Boat Hut Fishing is one of Australia’s favourite pastimes. At Boat Hut you can catch the best deals on a range of fishing accessories; from rod holders, knives, lures, downriggers, and more! Read More Here you will find a wide selection of fishing accessories and gear to enhance your fishing and boating experience. Our selection of fishing accessories includes everything from lures and baits to fishing line and rods. We carry products from top brands and manufacturers, ensuring that you get the highest quality gear for your money. Our lures are designed to mimic the look and movement of real bait fish, making them irresistible to even the wariest of fish. Our fishing line is made from durable materials, so you can be sure that you’ll be able to reel in that big catch. In addition to our wide selection of fishing and boating accessories, we also offer a variety of rod holders and fishing accessories storage options. Our rod holders are made from durable materials and are designed to securely hold your fishing rod while you’re out on the water. They are easy to install and adjust and come in…

- Bait Boards

Bait Boards for Boats Whether you are an experienced angler spending hours on the water or a casual weekend fishing enthusiast, our extensive selection of bait boards for boats is designed to meet all your fishing needs. Bait boards, also known as cutting or filleting boards, are indispensable tools for every fishing trip. For those new to fishing, a bait board provides a durable and hygienic surface for cutting bait, filleting fish, and performing various other activities that require a stable platform. Read More Choosing the perfect bait board for your boat can significantly enhance your fishing adventures. One popular option is the boat bait board. These specialised boards are crafted to mount easily onto your boat, offering a seamless fishing experience. They not only save valuable space on your vessel but also provide convenience while out on the water. Furthermore, they enhance safety by keeping all bait and fish remnants off the boat deck, creating a tidier and safer fishing environment for you and your crew. At Boat Hut, our comprehensive collection of top-quality bait boards is meticulously designed with the angler’s needs in mind. Whether you’re a seasoned pro or a beginner,…

- Boat Rod Holders

Boat Rod Holders Here at Boat Hut, we understand the importance of having high-quality rod holders on your boat. The term ‘rod holders’ may seem straightforward, but there’s more to these little gadgets than meets the eye. Rod holders play an integral role in a successful fishing venture, holding your fishing rods securely while you bait hooks, cast lines, or sit back and relax, waiting for the fish to bite. Read More Our extensive product range caters to a variety of fishing styles and boat types. Our boat rod holders are not just functional; they are also durable and robust, designed to withstand the harshest of conditions. They come in an assortment of materials, including high-grade stainless steel and durable plastic, to suit your specific needs and preferences. The practicality of our rod holders for boats extends beyond their primary function. Several of our models feature adjustability up to 360 degrees, ensuring you have the flexibility to position your rods exactly how you want them. Not sure about which boat rod holder is best for your boat? Check out our comprehensive article on the different types of rod holders and tips for proper installation.…

- General

- Hull, Deck & Cabin Hardware

- Anodes

Introduction to Aluminium & Zinc Anodes for Boats Sacrificial aluminium anodes for boats are specifically designed to protect those metal parts submerged and exposed in water and, unlike a traditional zinc anode, is completely calcium-free. Boat Hut provides a wide range of quality Martyr anodes including a zinc anode and round models to suit propeller shafts and rudders, block models for hull protection, complete kits for stern drives, outboards plus pencil models for diesel applications and other applications (e.g. heat exchanger). Read More In recognition of our delicate marine environment, Boat Hut introduces a range of pressure die-cast Martyr aluminium anodes for boats (Mil A 24779 SH). Where traditional zinc anodes use small amounts of Cadmium in the manufacturing process, all Martyr aluminium anodes are completely Cadmium free, being predominantly made of non-toxic aluminium and Indium. The Cadmium free anode offers many benefits and advantages over the traditional zinc type. In addition to being more environmentally friendly, the aluminium anode is significantly lighter for the same given volume, which can result in fuel savings where large zinc block anodes have previously been used. Martyr aluminium anodes offer improved performance and efficiency due to its…

- Bow Roller

Bow Roller As a boater or RV owner, you know how vital a reliable bow roller can be. At Boat Hut we provide an extensive collection of top-quality bow rollers. We understand that durability and efficiency are crucial when it comes to bow rollers, and that’s why we make sure to provide only the best products to our customers. Read More Our bow rollers are designed to make it easy to launch and retrieve your boat, providing a smooth and effortless experience. They are made from high-quality materials that are resistant to the harsh marine environment, ensuring reliable and long-lasting performance. We offer a variety of bow rollers to suit different types of boats and preferences, including rollers with self-locking mechanisms and those that can be locked in place for added security. We also offer rollers in various sizes and designs so that you can find the perfect fit for your boat or RV. We are committed to delivering top-quality products at reasonable prices, and our selection of bow rollers is no exception. Our bow rollers are crafted to provide the best possible boating experience, and we’re confident that they’ll meet and exceed your…

- Block

Blocks are essential to the boat’s hull, deck, and cabin hardware. They are used for various applications, from controlling sails to managing lines and rigging. Blocks come in various shapes and sizes and are typically made from materials such as stainless steel, aluminium, and composite plastics. They are designed to withstand the harsh marine environment and provide reliable performance for the boat owner. Regarding hull hardware, blocks are commonly used to manage lines and control sail shape. They can be found in various locations throughout the hull, such as at the mast base, boom, and traveller. On the deck, blocks are often used with cleats and winches to control lines and sails. They can be found on the cockpit, bow, and stern, and are often used to control sheets, halyards, and reefing lines. Blocks are also used in cabin hardware to manage various systems, such as the steering and propulsion systems. They can be found on the helm station and are used to control the boat’s direction and speed. Overall, blocks are an essential component of a boat’s hardware system, and play a crucial role in ensuring the safe and efficient operation of the vessel. Ready to upgrade your boat’s…

- Cleat

Cleats are essential to any boating or marine vessel, providing a reliable and secure way to fasten ropes and lines to the deck or dock. At Boat Hut, we offer a wide range of cleats designed to meet the needs of boaters and sailors of all experience levels. Our selection includes traditional horn cleats and modern cleats with sleek, low-profile designs. Made from high-quality materials such as stainless steel, aluminium, and composite materials, our cleats are built to withstand the harsh marine environment and provide years of reliable service. We offer cleats in various sizes and styles to accommodate different types of boats and vessels, from small recreational craft to large commercial vessels. Whether you’re looking for a classic, traditional look or a more modern, streamlined design, our selection of cleats has something to suit your needs. In addition to standard cleats, we also offer specialty cleats designed for specific applications, such as folding cleats that can be easily stowed away when not in use and pop-up cleats that provide a flush, low-profile mounting surface. At Boat Hut, we understand the importance of having reliable, high-quality equipment on board your boat or vessel. That’s why we only offer cleats from…

- Deck Filler

Deck fillers to securely fill and access fuel, water, and waste tanks from the deck of the vessel. These fillers are designed to be highly durable, weather-resistant, and easy to install. Deck fillers are available in a variety of materials including stainless steel, brass, and plastic. Stainless steel and brass options are corrosion-resistant and ideal for use in saltwater environments. Plastic options are lightweight, easy to install, and ideal for freshwater applications. Deck fillers are available in different sizes and shapes to fit different tank fittings. They are typically designed with a hinged lid or a screw-in cap to ensure they are tightly secured, preventing leaks and spills. Whether you’re a recreational boater or a seasoned mariner, having reliable and durable deck fillers is essential. At Boat Hut, we offer a wide range of deck fillers to suit your specific needs. Our products are sourced from top-quality manufacturers and are built to last, ensuring that you can enjoy your time on the water with peace of mind. Shop with us today to find the perfect deck filler for your vessel.

- Galley

- Hatches & Ventilation

Hatches & Ventilation We specialise in a wide range of hatches and ventilation solutions tailored for different boat types and sizes. Understanding the unique needs of boaters, we supply products from top manufacturers like Lewmar, Europa, Vetus, Jim Black, and SSI, known for their quality and durability to keep your boat secure and functional under any conditions. Read More Our selection also includes ventilation solutions ranging from solar vents, which help reduce humidity and prevent mould, to bilge blowers essential for removing engine area fumes and gas. Proper ventilation is crucial for both comfort and safety onboard. In addition to functionality, we know that the look of your boat matters too. Our range features various styles and finishes, from sleek, low-profile hatches that integrate smoothly with your deck to traditional designs that add elegance to your vessel. Whether upgrading an old hatch or fitting a new one, our products combine style with performance. Explore our extensive selection of boat hatches and ventilation solutions. With our broad range, top-quality brands, and expert advice, we’re confident you’ll find precisely what you need to improve your boating experience. If you’re still unsure about the best hatch or…

- Latches & Catches

Latches & Catches Latches and catches play a crucial role in securing various components of boats, ensuring their safety and functionality. These hardware devices are designed to keep doors, hatches, compartments, and other openings securely closed during navigation, preventing any unwanted movement or access. Boat latches are typically made from durable materials such as stainless steel, brass, or corrosion-resistant alloys. These materials are chosen for their ability to withstand the harsh marine environment, including exposure to saltwater, UV rays, and constant vibrations. Different types of latches are used in boats, depending on the specific application and the level of security required. Some common examples include: Compression latches: These latches use a cam mechanism to create a strong and tight seal, ensuring watertight compartments and hatches. Slam latches: Designed for quick and easy operation, slam latches allow for convenient one-handed closing and can be securely locked with a simple push. Twist latches: Utilizing a twisting motion to secure doors or hatches, twist latches are often used in smaller compartments or cabinets. Magnetic latches: These latches use magnets to hold doors or panels in place, providing a secure closure while still allowing for easy access. Boat catches are often paired with latches…

- Seating

Boat Seats Are you looking for premium boat seats at affordable rates? Boat Hut is a leading boating and marine accessories supplier in Australia. We have earned a great reputation in the marine industry by sourcing all our products from genuine manufacturers, and making sure that they adhere to our customer’s needs and desires. There are a number of characteristics of boat seats that our customers seek, i.e. an adjustable reclining seat, finish, quality, durability secure/strong mounts and comfort. Yes, we make sure that these requirements are met within the desired budget of our customers. Visit us to know more about our range of premium boat seats, and let us help you find the one you really want! Boat Seats Online in Australia We have a large range of different models of boat seats at attractive rates, so visit us now! If you are concerned about buying boat seats online, don’t worry, all our products are tested to ensure they adhere to our high-quality standards, and only then they are supplied to our customers. We are here to cater to all your boating requirements, and make sure your experience is safe , comfortable and fun. We have stocked different models…

- Sheet Winches & Accessories

Sheet Winches & Accessories Sheet Winches & Accessories form a critical component in the world of boating. They are the unsung heroes, ensuring that your boat sails smoothly and you have complete control over the sails. As the name suggests, Boat Sheet Winches & Accessories are specifically designed for boats, supporting sail adjustment and control. Read More Lewmar® stands out as a global leader in yachting winches, preferred by cruisers and racers globally. Combining premium materials with precise CNC machining, Lewmar® winches ensure efficiency, durability, and strength, while minimising weight. They’re available in several materials like bronze, aluminium, and carbon fibre, in formats such as standard, self-tailing, electric, and hydraulic. Easy to install and service without special tools, Lewmar® winches are designed for accessibility to components for maintenance. A full range of spare parts and maintenance supplies ensures years of reliable performance. Choosing the right winch involves matching your application and yacht size to the appropriate winch size and type, considering purchase systems and expected loads. The EVO® Winch Range offers a wide selection of sheet winches in standard and self-tailing formats, available in finishes from size 6 to size 80, designed for…

- Marine Pumps and Plumbing

Boat Hut has Australia’s leading range of waste water, grey water, pressure and bilge pumps. Our range includes manual, electric and automatic bilge pumps from the leading international suppliers. We carry Rule, Whale, Johnson, and Attwood. Boat Hut has access to the entire product ranges for the brands listed above. If the pump or accessory does not appear on our website then please feel free to give us a call to provide you a competitive quote. Not sure what pump you need for your boat? Check out our guide on marine pumps or get in touch with our friendly staff.

- Aerator Pumps

Aerator Pumps/Livewell Pump Maintaining a healthy environment on your boat is crucial, especially when it comes to keeping your bait or catch in top condition during fishing trips. A key component in achieving this is using an aerator pump. An aerator pump for boats ensures that the water within bait tanks or live wells is oxygen-rich, creating an ideal habitat for your bait. Read More An aerator pump for a boat works by injecting air into the water, which increases oxygen levels and promotes healthier water conditions by reducing stagnation. This is particularly important on a boat, where oxygen levels can quickly deplete, potentially harming the bait. The operating principle of an aerator pump system is straightforward yet effective. Air is pushed into the water, causing bubbles to circulate and rise. This process not only adds necessary oxygen but also helps distribute it evenly throughout the tank. The result is a well-oxygenated environment that keeps your bait lively and responsive. Boat aerator pumps are available in various sizes and capacities, ensuring there is an appropriate option for every type of boat. Whether you have a small recreational fishing boat or a larger commercial vessel,…

- Bilge Pumps

Boat Bilge Pump for Sale Boat Hut is the leading supplier of boat bilge pumps and marine accessories in Australia. We offer a wide range of products, including different models to meet various requirements. We source our bilge pumps from genuine manufacturers to ensure high quality and efficient operation, keeping you and your family safe in case of emergencies. We provide all our bilge pumps at very competitive rates. Explore our store, to find the right bilge pump for your vessel, at a fantastic rate. Read More How Does a Bilge Pump Work? To understand the type of bilge pump you need, you first need to understand how a bilge pump works. Here are some common points that describe the workings of a bilge pump: The liquid enters the pump through an opening at the center of the impeller (eye of the impeller). It then flows radially out to the impeller’s vanes. Due to the rotation, the liquid’s velocity increases. This high-velocity liquid enters the volute casing or diffuser, where the kinetic energy is converted into pressure. The pressurised liquid is pumped out through the pump discharge. Larger crafts require larger bilge pumps to…

- Bilge Blowers & Float Switches

We offer 75mm and 100mm standard & heavy duty bilge blowers. We also offer a full range of Float Switches and accessories online and instore. What is a bilge blower? A Bilge Blower on a boat is a fan that is used to remove flammable fumes from the engine compartment. This is to help prevent an explosion in the engine compartment whenever the engine is turned on after sitting for an extended period of time. The fumes that build-up are usually caused by a leak in a gas line or hose.

- Fittings & Valves

- Impellers

What Impeller Do I Need? Selecting the Right Impeller We carry pump impellers from several manufacturers that suit Johnson Pump, Mercury Marine, Sierra and Jabsco. The water pump impeller of any outboard motor needs to be serviced on a regular basis, usually annually, this helps to maintain pump performance, function, cooling and power. However, most owners we deal with do it less often and can end up with greater issues. Read More It is a wise idea to keep a spare impeller on board just in case that your impeller fails — an impeller failure at the wrong time can be disastrous. Flexible impeller pumps are common in shower drain sump pumps, some bilge pumps, wake board ballast pump systems, oil changing systems, Shower pump and lots of other applications. HOW DO IMPELLERS BECOME DAMAGED? Your boat’s impeller is a series of rubber impeller vanes moulded around a hub. The tips of these flexible vanes can wear out for a variety of reasons including simple use or if the boat is in sandy water. Abrasive sand like material can cause the impeller to wear out faster. Impellers can also wear out by becoming stiff…

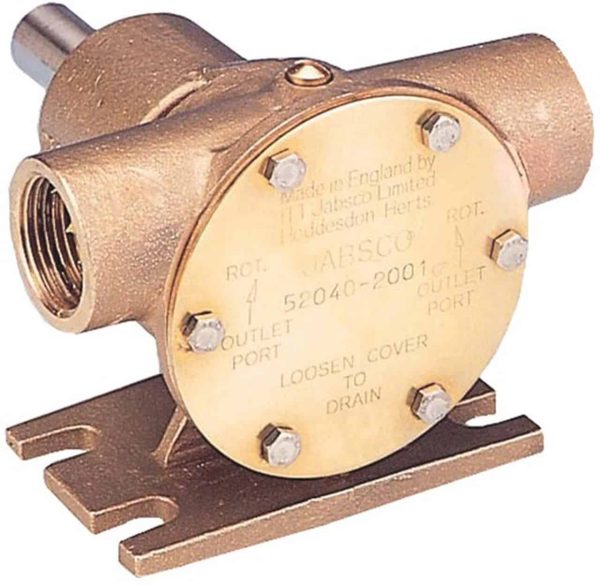

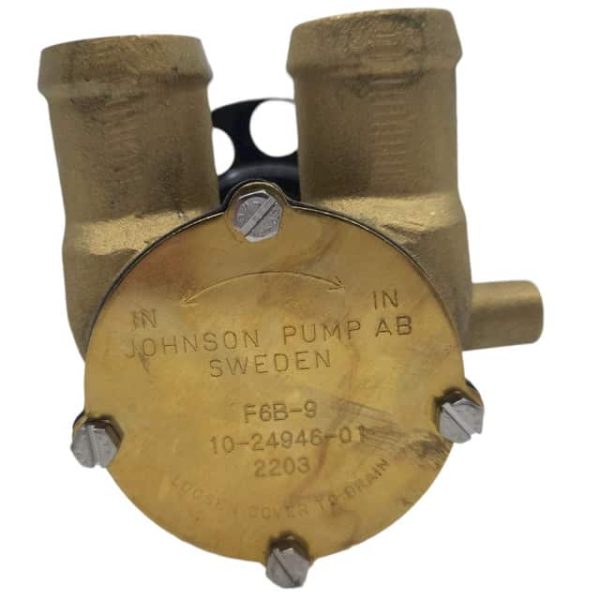

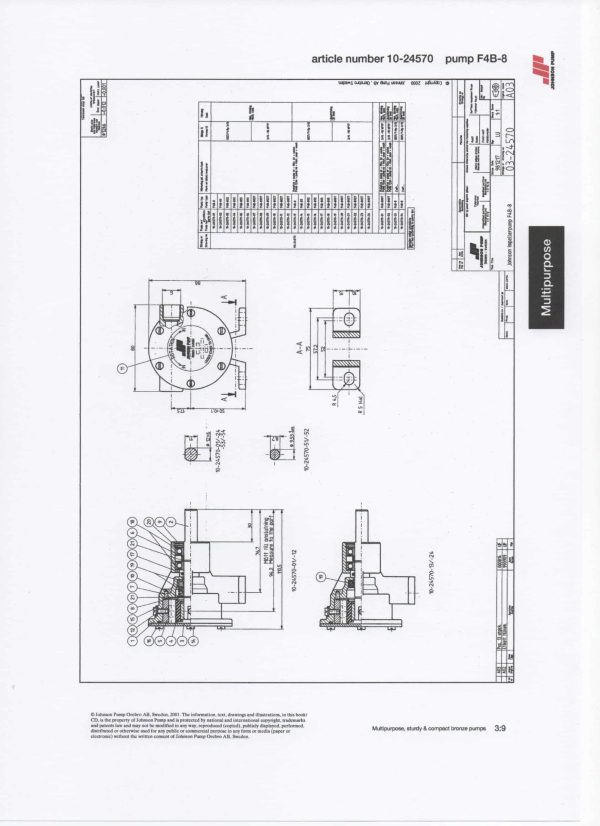

- Impeller Pumps

Impeller Pump A flexible impeller pump provide an efficient solution to most raw water pumping needs. The pumps are self-priming and can pass fairly large solids without clogging or damaging the pumps. Our engine cooling pumps are designed to the demands of engine manufacturers and are built to take rough treatment. We supply engine cooling pumps to the world’s leading marine motor manufacturers, not just because of our renowned pumps; but also because of our advanced original impeller design and technology – the heart of an engine cooling pump. Read More With their high level of flexibility, these pumps are ideally suited for use in boats as bilge pumps, deckwash pumps, fresh water pumps and refuelling pumps for oil and diesel. These pumps may be combined with a vacuum switch for automatic operation. Full range of capacities from 15 – 55 l/min. All motors are heavy duty to provide long service life even under heavy use. Available in 12 or 24 volts. FLEXIBLE IMPELLERS – OPERATING PRINCIPLE • A vacuum is created as the flexible impeller vanes straighten upon leaving the cam, drawing liquid into the pump. • The rotating impeller carries liquid from…

- Toilets

Boat Toilets Boat toilets serve as a fundamental component in ensuring comfort and convenience aboard any vessel. Also known as marine toilets, these specialised units are specifically designed to withstand the unique conditions on the water, providing essential sanitary facilities for long and short voyages alike. Read More In Australia, a country renowned for its marine culture and vast coastline, boat toilets are particularly important. The country’s love for boating activities makes toilets for boats a sought-after commodity, with numerous designs and models available catering to different boat sizes, types, and user preferences. One of the primary considerations when choosing a boat toilet in Australia is the type of sanitation system. We stock a wide range of boat toilets and boat toilet parts, offering options for every boating enthusiast. Given the marine environment’s harsh conditions, investing in a high-quality, corrosion-resistant unit is advisable. Units made from tough plastics, stainless steel, or porcelain can withstand the rigours of the sea, ensuring longevity. With proper care, a good quality boat toilet can last for many years, making it a worthy investment. So while it may look like a simple piece of equipment, boat toilets involve some…

- Water Pumps

Electric Water Pumps Boat Hut has a large range of electric water pumps designed for a variety of applications: Pressure pumps Wash down kits Submersible pumps Inline pumps 12 volt pumps 24 volt pumps Marine pumps Caravan water pumps RV Pumps Some pumps can handle both water and Diesel applications Read More Industry Leading Electric Water Pumps Boat Hut’s range of manufacturer’s include Whale, Rule, SPX Johnson, Flojet, Shurflo and Jabsco. We have access to a comprehensive range of spare parts. Boat Hut has a wide range of Boat and Marine accessories and we ship Australia wide. We are happy to order in any specialist product from our suppliers. Please feel free to contact us if you have any questions or would like a product not listed on our website. Why Choose One of Our Electric Caravan Water Pumps? At the Boat Hut our goal is to supply our clients with the right water pump for them. Our electric water pumps have industry leading technology. When it comes to preserving your caravan, an electric caravan water pump is essential. It prevents water from collecting in unwanted places, which can ultimately lead to damage to your vehicle. By investing in…

- Water Pump Repair Kits

Boat Water Pump Kits We understand the importance of a reliable water pump kit in maintaining optimal boat performance, safety, and longevity. Our extensive range of water pump kits is meticulously designed to keep your boat’s cooling system running efficiently, preventing engine overheating and ensuring smooth sailing. Read More Whether your boat has a 2-stroke or a 4-stroke engine, we might have the right water pump kit to meet your specific requirements. We have access to a large and extensive water pump kit catalogue of kits currently available so check out our water pump kits section to know what we have currently on sale Or email us with the part number you require if you can’t find it on a our website Our category boasts a comprehensive collection of water pump kits from leading brands like Sierra & GLM. We also have access to OEM products, renowned for their quality, durability, and innovation. We offer kits with or without housing, allowing you to choose based on your boat’s specifications and preferences. When you invest in a Sierra Water Pump Kit from our collection, you invest in a product that promises exceptional performance, easy installation,…

- Lighting

Lighting At Boat Hut we provide a wide range of high-quality lighting products designed specifically for marine use. Whether you need lighting for safety, convenience, or aesthetic purposes, we have the right products for your needs. Read More Our waterproof strip lights are perfect for adding ambient lighting to your boat or RV. They are easy to install and can be cut to size to fit your specific needs. They are also waterproof and durable, ensuring that they provide reliable performance for years to come. Our stainless steel LED Bunk Light is a sleek and stylish lighting solution for your boat or RV’s sleeping area. It is easy to install and features energy-efficient LED bulbs that provide bright and long-lasting illumination. For small boats, we offer battery-operated LED navigation lights that are compact and easy to install. They are perfect for use as emergency lights or as a backup lighting system. Our Bi-Colour horizontal mount navigation lights stainless steel are an essential safety accessory for any boater. They provide bright and reliable illumination and are designed to withstand the harsh marine environment. We also offer anchor lights to ensure that your boat is visible…

- Interior Boat Lights

Interior Boat Lights We offer a comprehensive range of lighting solutions specifically designed for marine use. Our products are carefully chosen to ensure your boating experience is well-lit, safe, and enjoyable. Whether you’re looking for a practical way to illuminate the deck or a subtle accent light to enhance your boat’s aesthetic, our selection of interior boat lights is sure to have something for every need. Read More Our interior boat lights range includes various options designed to meet all your needs on the water. From waterproof strip lights that are as robust as they are bright to 12v – 24 boat light interiors that are perfect for all types of marine craft, we have a vast array of options that are purpose-built to withstand maritime conditions. We’ve seen our customers use our variety of lights, including the sleek stainless steel LED bunk light or the compact dome LED light, innovatively turning their marine vessels into a sight to behold when the sun goes down. Our boat interior lights are not just functional, but they also add a touch of elegance to your boat’s interior. Our 12v boat lights interior selection is designed for…

- Underwater Boat Lights

Underwater Boat Lights Underwater lighting is not just a stylish addition to your boat, but it also enhances safety and functionality. At Boat Hut, we understand the essence of quality underwater boat lights, and that’s why we bring you a wide array of top-of-the-line options. Providing the perfect blend of aesthetics and performance, our lights have been proven to be among the best underwater boat lights available in Australia. Read More Our underwater lights are designed to illuminate the water surrounding your vessel, creating a mesmerising glow that is certain to make heads turn. Whether you wish to go fishing at night, take a rejuvenating dip in the glistening water, or add an extra layer of safety to your boating experience, Boat Hut’s underwater boat lights are just the solution. While there are several types of underwater boat lights available in the market, LED underwater boat lights stand out for their energy efficiency and long-lasting durability. LED lights are known to produce brilliant illumination while using minimal energy, making them a cost-effective lighting solution for your boat. Invest in our underwater boat lights and experience the difference for yourself. Navigate through our comprehensive collection…

- Muir Winches & Windlasses

Muir Winches & Windlasses Muir Windlasses Australia specialises in the manufacture of high-quality, Australian-made windlasses and anchoring systems that stand the test of time. They equip vessels from five metres to 150 metres and have the most extensive range of anchor windlasses and equipment available on the world market. From pleasure craft and superyachts, to a spread of commercial vessels, Muir’s range is comprehensive and known for its superior technology. Muir products are exported to more than 50 countries worldwide from our Tasmanian head office, manufacturing and design facilities. Muir also holds warehousing and sales facilities in Sydney, the Gold Coast, Florida USA, and Southampton UK, together with a very strong distribution network which covers the rest of the globe. Muir has firmly established itself as a market leader in the design and manufacture of its products both within Australia and overseas, and is renowned for its high-quality, performance and reliability. With nearly half a century of combined experience in anchor windlass technology, Muir technicians and engineers have designed and developed a superior range of pleasure craft windlasses and products that meet the requirements of the most discerning clients and their vessels. https://www.muir.com.au/ We have access to the Muir range…

- Navigation

Compass Navigating the waters around Australia requires a good compass. It’s an essential tool for boaters, whether you’re out for leisure or getting from point A to B. The market has lots of compass options, from simple ones that mount on the dash to high-tech digital models for bigger boats. Read More Modern compasses aren’t just functional; they can also look good on your boat. You can find them in different styles to match your boat’s look. The Plastimo Compass series, for example, offers both black and white options to fit right in with your boat’s design. When properly sized, installed, and compensated, a marine compass becomes the most important instrument on any boat. It uniquely stands out by delivering accurate, trouble-free heading references under the most adverse conditions, operating independently of electricity, radio signals, or satellite communications. Two important criteria in selecting an compass for your journeys are the dial size and the mounting style. These elements ensure that the compass can be easily read and securely affixed in a manner that complements the boat’s design and the captain’s navigational needs. Quality components are essential for ensuring accuracy, smooth response, stability, and straightforward…

- Boat Compass

Boat Compass for Sale When properly sized, installed and compensated a marine compass is the most important instrument on any boat. It will provide accurate, trouble-free heading references under the most adverse conditions without relying on electricity, radio signals or satellite communications. The most important criteria when selecting a boat compass are dial size and mounting style. Quality components aid accuracy, smooth response, stability and simple operation. We stock a large range of Ritchie Compass, Plastimo Compass, Silva and other brands of boat compasses for sale. When it comes to boating and marine activities, having a compass is crucial for several reasons. Here are some compelling arguments for buying boat and marine compasses: Navigation on Open Water: Boat and marine compasses are specifically designed to provide accurate navigation on open water. They help boaters determine their heading and maintain the right course, ensuring a safe and efficient journey. Whether you’re sailing, fishing, or cruising, a compass is an essential tool for navigating unfamiliar waters. Safety at Sea: Boating in open water can present challenges such as fog, low visibility, or adverse weather conditions. In these situations, relying solely on electronic navigation systems can be risky. A boat compass acts as…

- Oil

Oil for boats At Boat Hut, we understand the importance of keeping your boat’s engine running smoothly. That’s why we are proud to offer a comprehensive range of boating oils and lubricants from top brands like Sierra, Valvoline, and SeaStar. These products are designed to keep your boat’s engine protected from wear and tear, ensuring that it runs smoothly and efficiently, no matter how far you venture out on the water. From high-quality engine oils to specialised lubricants for steering and control systems, we have everything you need to keep your boat in top condition. Our selection includes a range of products that are specifically formulated to meet the unique needs of your boat, whether you’re using it for fishing, cruising, or simply enjoying a day out on the water. At Boat Hut, we are committed to providing our customers with the best possible shopping experience, and that’s why we offer a 30-day return policy and 24/7 buyer support. If you have any questions about our products, our friendly and knowledgeable customer support team is always here to help. Browse our selection of boating oils and lubricants today and find everything you need to keep your boat running smoothly.

- Sealant

Sealant seals gaps, cracks, and joints between different surfaces. In a marine environment, sealant is not just another product, but an essential component of boat maintenance. The sealant keeps the boat watertight by preventing water from entering through seams and joints. Read More We offer a wide range of high-quality sealants for marine applications. Whether you’re sealing hulls, fixtures, or components, our selection includes trusted brands like Fixtech and 3M™, known for their reliability and performance in challenging marine environments. Sealants are essential for any boat owner looking to protect their investment. They help prevent leaks that could lead to costly repairs and compromise the vessel’s safety. Using the right sealants also prevents mould and mildew in enclosed spaces, such as cabins and storage compartments, by creating a watertight barrier. When choosing the right sealant, consider the materials, application location (above or below the waterline), and the desired look. For example, if you prefer a clear, invisible finish, a silicone-based sealant may be the ideal choice. Our team is ready to help you find the best option, ensuring you have the right product for your project. Explore our selection today for sealants that deliver…

- Outboard Parts

Outboard Parts Do you love to go out in the water now and then? Do you own outboard engines? It is challenging to find the right parts for outboard engines because of the variety of models available worldwide. The parts required are particular, and you cannot take the risk of spending your hard-earned money on parts you are unsure of! So what can resolve this issue? Look for trusted companies that offer outboard parts that fit your model. Boat Hut is a preferred outboard parts supplier in Australia because of the quality and variety of parts that we have available ! Outboard Parts Online for Sale Australia If you are looking for outboards parts online, then visit Boat Hut right away! It is obvious that you would not prefer buying a new engine, if your outboard stops working. Give us a call and we can let you know what we can supply for our outboard and refer you to specialists for your make and model. We will do the leg work to find your part if it is available. We have access to a range of service technicians and professionals that have years of industry experience. Our focus is on…

- Fuel Filters & Fittings

Boat Fuel Filters & Fittings Whether prepping for a leisurely day on the water or setting sail on the open ocean, ensuring a clean and efficient fuel system is paramount to your journey’s success, our extensive range of Boat Fuel Filters and fittings are designed to keep your boat’s engine running smoothly and your adventures on the water uninterrupted. Read More A boat fuel filter plays a crucial role in the performance of your marine engine. The fuel filter ensures optimal engine performance and longevity by removing impurities and contaminants from the fuel before it reaches the engine. Our selection includes products like the Marine Water Separator Fuel Filter from Mercury, which effectively separates water from the fuel to prevent potential engine damage. Similarly, the 21 Micron Merc Fuel/Water Separating Filter from Sierra is designed to provide your boat with cleaner, better quality fuel while protecting your engine’s components. On the other hand, fuel fittings serve as crucial connectors in your boat’s fuel system. They secure the link between your fuel lines and the engine, preventing leaks and ensuring a steady fuel supply. Our Sierra Fuel Line Connectors and BLA Fuel Tank Adaptors are…

- Jack Plates

Jack Plates Boat Hut offers a wide range of boat Jack Plates to cater to boating enthusiasts. While Jack Plates are an integral component for some boats, not all boats require or have them. They provide height adjustment for the outboard motor, impacting speed, fuel efficiency, and handling. Read More We offer both manual and hydraulics jack plates, Whether you need Jack Plates for a small personal watercraft or a large commercial vessel, our collection has something for everyone. Our category boasts a variety of Jack Plates, including the standard and Xtreme versions for different set-backs. We offer Seastar Hydraulic Jack Plates in 4″, 6″, 8″, 10″, and 12″ set-backs in both standard and Extreme models. These Jack Plates for boats come with an option for a Smartstick, providing a visual guide for the plate’s current position. The Seastar Jack Plate Pro Tap comes in two variations: Flats Mode and Bay/Bass Mode, designed specifically for the needs of different boating environments. Additionally, we provide Seastar Jack Plate Hole Shot Plates in multiple sizes to improve your boat’s acceleration in shallow water. We also offer another brand called Bobs Machine Shop. For your convenience, we…

- Oil Filter

Oil Filters We understand that maintaining your boat is just as important as enjoying it, and that’s why we offer a comprehensive range of boat oil filters suitable for various boat models. When it comes to maintenance, the oil filter is an essential component that should always be noticed. This simple yet integral part of your boat’s engine ensures the oil remains free of impurities that can damage your engine’s internal components over time. Regularly replacing your oil filter for the boat ensures a smooth and efficient operation, prolonging the lifespan of your boat’s engine. Read More Our Oil Filter category houses a diverse selection of products, each manufactured to meet the specific requirements of different boat engines. From Mercruiser to Suzuki, Evinrude Johnson to Honda/Yamaha, we offer oil filters compatible with various boat engines. Whether it’s the SIERRA Oil Filter S18-7824 Mercruiser or the Sierra Oil Filter for Honda/Yamaha BF25, BF30, BF40, and BF50, our collection is designed to cater to a variety of needs. We also offer a selection of other renowned brands, including Sierra, Fleetguard, and Volvo Penta. Not only do we prioritise quality and diversity, but we also focus on…

- Spark Plug

Spark Plugs We’re your go-to source for the best spark plugs in the marine industry. Our range of spark plugs is designed to keep your boat’s engine running smoothly and efficiently, ensuring you can navigate the waterways confidently and safely. Read More In the boating world, a spark plug is more than just a component; it’s a lifeline connecting your boat to the water. Every spark plug in our collection is carefully selected to provide maximum performance to your boat’s engine. With us, you can find a line of spark plugs that are resilient, reliable, and robust, making sure you’re always ready for your next aquatic adventure. Spark plugs are crucial for the smooth operation of your boat’s engine. They are needed to ignite the fuel within the engine’s cylinders, enabling your boat to easily power through the water. In choosing the right spark plug for your boat, you’re choosing to invest in its long-term performance and durability. We understand the unique demands of marine engines. That’s why we provide a range of spark plugs specifically designed for boats; each spark plug in our collection is built to withstand the challenging conditions of marine…

- Boat Propellers

Boat Propellers Looking for a propeller that will take your boating experience to the next level? Look no further than Boat Hut’s extensive range of boat propellers! Whether you have an outboard or a sterndrive, our selection of Stainless Steel and Alloy Outboard boat propellers are sure to meet your needs and exceed your expectations. Read More Whether you’re in need of an outboard or sterndrive propeller, we have you covered with our extensive range of high-quality products from leading brands like Sierra, Wrench, and Seastar. Our boat propellers are designed to offer optimal performance, providing the right combination of thrust and speed to get you where you want to go. Our stainless steel outboard boat propellers are designed to offer superior corrosion resistance, while our alloy outboard boat propellers offer a cost-effective option that’s both lightweight and strong. If you’re looking for a sterndrive propeller, we have a variety of options to choose from, each designed to provide the right amount of performance and stability. At Boat Hut, we’re committed to providing our customers with the best possible shopping experience. That’s why we offer a 30-day returns policy and 24/7 buyer support. If…

- Rope

Rope Discover the Ultimate Rope for Your Boat at Boat Hut! From mooring lines to anchoring ropes, Boat Hut has got you covered with our wide range of boat ropes, available in a variety of materials and constructions. Our knowledgeable staff is here to assist you in choosing the right rope for the right job, ensuring you get the best product to suit your boating needs. Read More Unleash the Power of Nylon Rope – The Strongest of Them All! Nylon rope is known for its superior strength and high energy absorption capabilities. However, keep in mind that its strength decreases by 15% when wet, making it suitable for applications that are protected from water exposure. With high resistance to UV, heat, and abrasion, nylon rope has a long lifespan, making it an excellent choice for various boating applications. Get the Best of Both Worlds with Polyester Rope Polyester rope is almost as strong as nylon, but it doesn’t lose strength when wet. With excellent resistance to abrasion, UV, and heat, polyester rope is an ideal choice for applications where stretch is not desired, such as sheets and halyards on sail boats. Stay Afloat…

- Safety Equipment

Safety Equipment Boat Hut has a comprehensive selection of safety equipment to ensure you and your passengers are protected on the water. Our product line includes life jackets for adults and children, flare kits, fire extinguishers, BLA equipment, and PFD products. We understand the importance of keeping you and your family safe, which is why we strive to offer the best safety gear on the market. Read More Life jackets are an essential piece of safety equipment for anyone on the water. Whether you’re an experienced sailor or a beginner, we have the right life jacket for you. Our life jackets are made from high-quality materials and are designed to provide the ultimate in comfort and safety. Our infant and kids life jackets come in a range of bright colors, making them easy to spot in the water. Flare kits are also an important safety tool in case of emergency. Our kits include a variety of flares and a whistle to help you signal for help. In the event of a fire, a fire extinguisher is an essential tool to have on board. Our fire extinguishers are designed to be compact, easy to use,…

- Personal Location Beacon

Personal Location Beacon Exploring the waters, whether for leisure or professional undertakings, demands skill and a profound commitment to safety. In this regard, Personal Location Beacons (PLBs) are indispensable tools for any mariner, adventurer, or casual boater. Read MoreSpecifically designed for marine use, these beacons are engineered to withstand harsh conditions, including submersion in water. Their robust construction ensures functionality even in the most adverse scenarios. This device sends out an emergency distress signal and provides GPS coordinates to the rescue services, significantly reducing response time and increasing the chances of a successful rescue. Using a Personal Location Beacon for boats in Australia isn’t just about adhering to safety norms; it’s a practical measure that adds an essential layer of security when navigating the unpredictable nature of the sea. From professional fishermen venturing out for their daily catch to families enjoying a weekend sailing trip, the presence of a PLB is a testament to their commitment to safety and preparedness.

- PFDs & Life Jackets

Life Jackets Personal flotation devices are an extremely important part of maritime safety and they are regularly referred to as PFDs or life jackets. They are used in many types of marine and water activities including boating, jetskis, water sports, fishing and any activity around water. There is a legal requirement for all watercraft to carry a life jacket for all passengers excluding very small recreational craft – please refer to your local authorities, regulations and standards for details of the exact requirements for your circumstances. Boat Hut has a range of life jackets for sale accommodating babies from 5 kg through to infants, toddlers, kids and adults, up to a XXXL and over 80 kgs. There are ranges with colour options designed for both male and female and include camouflage. No matter what you are doing on the water we have a PFD that will suit your activity and personal preferences. Please feel free to give us a call on 07 3274 2221 to discuss your safety needs as we stock a wide range safety equipment ranging from flares, V Sheets and even EPIRBs. Life Jackets for Sale.

- Kids Life Jackets

Kids Life Jackets Whenever you take your kids out on a boat, it is extreamly important to fit them with the correct kids life jacket. Browse through our range of kids life jackets and get in touch if you have any questions. Kids Life jackets are available in various colours, sizes and specifications. You can choose a simple foam construction which will allow you to float and there are other models which are more compact and can inflate when you pull the cord or even some have the ability to automatically inflate when they enter the water. Children’s Life Jackets There are a number of Australian standards and categories that life jackets fall into and it is important to ensure that you choose the correct children’s life jacket for the activity you are undertaking. Most categories are designated by the location, generally this is distance offshore or inshore of the activity you are undertaking. For example, water skiing children’s life jackets are very different to open water yachting 5 miles off the coast. The children’s life jacket you would use for 5 miles off the coast is also different to the one you would require only 1 mile off the…

- Infant, Baby and Toddler Life Jackets

Infant, Toddler and Baby Life Jackets If you are taking your children out on the water, it is essential you fit them with the correct life jacket. Baby, Toddler and Infant Life jackets come in a variety of sizes, specifications, colours and capabilities. The most common type of PFD (personal flotation device) is a straight forward foam construction which will allow you to float. Infant, toddler and baby life jackets come with foam construction only. All our kids life jackets / life vests meet the Australian Standard. Read More Children & Kids Life Jackets At the Boat Hut it’s our mission to supply our clients with baby, toddler and infant life jackets that will keep their loved ones safe. Feel free to give us a call on 07 3039 3100 to discuss your safety needs as we stock a wide range of infant, toddler and baby life jackets for your baby, infant and toddler. Baby Life Jackets start at 5- 10kgs and then progress to Infant life jackets 10 to 15KG and then the largest if 15kg to 25kg before progressing into the children range of Life jackets / PFDs FAQs What is a child’s…

- Boat Steering Kit

Boat Steering Kit A Boat Steering Kit Dedicated To Command And Control SeaStar Solutions have put boaters in command and control of their vessels for over 60 years. From throttle and shift control cables to a new boat hydraulic steering bleeding kit, to instrumentation and repair parts for your engine and drive, SeaStar Solutions (formerly Teleflex) continues to lead the recreational marine industry with innovation, quality and a commitment to supplying boat builders, dealers and boaters with the boat steering kit parts they need, when they need them. It’s this dedication that has kept SeaStar Solutions® at the forefront of the industry. Read More No FeedBack Steering for Outboards (NFB) A boat hydraulic steering kit exist in all outboard powered boats. These steering loads are actually turning energy from your engine’s propeller. NFB steering locks out the prop feedback load which causes hard to handle steering. With NFB the wheel doesn’t turn until you turn it. How to measure boat steering kit cables Measure cable routing path from wheel centre line to engine connection as follows: • A – Centre line of wheel to gunwale (or deck, if routed downward) • B – Dash…

- Hydraulic Boat Steering

Hydraulic Boat Steering Boat Hut has access to a large range of hydraulic boat steering systems, cylinders, kits and spare parts including seal kits. The brands available include – Seastar (previously Teleflex), Baystar, Multiflex, Ultraflex, Optimus, Caplilano and Hydrive. Please refer to the Seastar and Baystar selection guide (please click link)- Seastar Baystar Hynautic Hydraulic Steering Selection Guide 2018 We can supply hydraulic boat steering cylinders, helms, bezels, seals, oil and outboard hoses. We have these available separately and in various steering kits. Read More What is hydraulic boat steering, and how does it work? Hydraulic boat steering is a method of steering that uses oil via flexible hoses to transmit force from the steering wheel to the outboard motor. Hydraulic boat steering systems are relatively exempt of frictional loads from engine torque and similar as most of the moving parts are running on ball bearings and in oil. This makes them more reliable, efficient, and they require less maintenance than mechanical cable type steering. Turning the wheel pumps fluid (Hydraulic oil) from the helm through the hoses and into the cylinder. The cylinder moves the ram which in turn moves the engine through…

- Steering Wheels

Boat Steering Wheels Boating in the pristine waters that Australia offers is an adventure like no other. One integral part of this nautical experience is the boat steering wheel. Many might overlook its importance, but the boat steering wheel is the heart of navigation, making it an essential consideration for every boat owner. Read More Boat steering wheels come in a variety of designs and materials to suit different types of boats and individual preferences. From classic to contemporary, the range spans across multiple styles. Aesthetics, while important, should not be the only determining factor when choosing a steering wheel for your boat. The steering wheel’s functionality, diameter, durability, and ease of installation also play a crucial role in the selection process. When purchasing a boat steering wheel, make sure it’s made from high-quality, corrosion-resistant materials to ensure longevity and performance. As boats are exposed to harsh marine conditions, selecting a steering wheel that can withstand these elements is vital. Steering wheels in Australia are often made from stainless steel or marine-grade polymer for this reason. We sell a fantastic selection of boat steering wheels for all types of boats, but keep in mind…

- Trim Tabs & Thrusters

Boat Trim Tabs & Thrusters Make the most out of your boating experience with the latest technology in boat trim tabs and thrusters. Whether you’re looking for better speed and maneuverability, or simply looking to add a touch of style to your vessel, our range of products has you covered. Read More We offer a wide range of boat trim tabs and thrusters, including spare parts, fuse holders, and bow & stern tunnels. Our products are designed with the latest technology, ensuring that they provide the best possible performance and reliability. Our range of spare parts, such as fuse holders, ensure that you can keep your boat trim tabs and thrusters in top condition. Our team of experts are available 24/7 to help you with any questions you may have about our range of boat trim tabs and thrusters. We offer a 30-day return policy, giving you peace of mind when purchasing from us. Whether you’re looking for new trim tabs and thrusters or simply need spare parts to keep your existing setup in good condition, we’re here to help. With our commitment to quality, value, and customer satisfaction, you can trust that you’re…

- Watersports

Watersport Accessories At Boat Hut, we understand the thrill of gliding across the water and the excitement that comes with it. That’s why we offer a range of boating and watersport products designed to enhance your experience on the water. From ski ropes to wakeboards, person tubes to dry bags, we have everything you need to make the most of your time on the water. Read More Ski Ropes: Our ski ropes are made with high-quality materials and designed to provide you with a smooth, stable pull behind your boat. They are available in a variety of lengths and strengths to suit your specific needs. Dry Bags: We offer BLA waterproof bags in various sizes, including the Bag Waterproof Blue 750X300mm 40L, 500X250mm 20L, and 500X200mm 12L, to keep your belongings safe and dry while in the water. These bags feature a reinforced top closure and a reinforced bottom, perfect for storing heavier objects like phones, cameras, and other valuables you want to protect from water damage. The clear, see-through PVC lets you easily see what you need without unpacking the entire bag. They come in transparent PVC with a blue/red bottom and handle.…

- RV Parts and Accessories

RV Spare Parts and Accessories Our range of RV products is designed to enhance your travelling experience, ensuring you have everything needed for comfort on the road. Our selection includes water pumps from renowned brands like Jabsco, known for their quality and reliability. We also stock Whale High Flow Submersible Water Pumps, ideal for RVs with high water demand. These pumps are compact and energy-efficient while providing a strong, consistent water supply. Read More In addition to our water pumps, we offer a comprehensive range of interior lights to brighten your RV space, ensuring comfortable and well-lit accommodations wherever you travel. Our selection of drinking water tanks is designed for convenience and easy installation, providing ample storage for your water needs without compromising on space. To efficiently fill these tanks, we provide high-quality transfer pumps for quick and reliable water supply. We also sell Whale Tiptoe Mk4 Foot Galley Pumps and Whale Watermaster RV On Board Pressure Pumps. Our selection includes galley pumps for your kitchen needs, waste pumps for efficient wastewater management, and shower drain pumps to keep your bathing area free from excess water. We stock a number of reputable brands, tested…

- Boat Maintenance

Boat Maintenance Equipment Boat maintenance is not just about aesthetics; it’s crucial for safety, durability, and performance on the water. Whether you’re a weekend sailor or a daily water enthusiast, understanding the basics of boat maintenance can make your time at sea both enjoyable and safe. Although maintaining a boat may seem daunting, with the right supplies and a little knowledge, anyone can keep their boat in excellent condition. Read More Routine checks form the backbone of effective boat maintenance. This involves looking beyond the surface to ensure everything from the hull to the engine is in working order. For example, inspecting the hull for signs of wear and tear can prevent water ingress, while checking the engine can save you from unexpected failures at sea. Remember, prevention is always better than cure, especially when you are miles away from shore. Using quality boat maintenance supplies can significantly impact the longevity and functionality of your boat. Whether it’s choosing the right oil for your engine, selecting a durable sealant for leaks, or finding a fuel filter that keeps your system clean, opting for high-quality products is a wise investment. With a variety of products…

- Air Filter

Boat Air Filters Engines, like humans, require clean air to function efficiently. While out on the water, your boat’s engine inhales a significant amount of air. If this air contains debris such as dust, sand, and bits of leaves, it can damage the engine over time. The boat air filter plays a critical role here, capturing these particles before they can enter the engine and cause harm. Read More When selecting an air filter for your boat, it’s essential to choose the appropriate one. Each boat has a specific type of filter that matches its engine. Using the correct air filter ensures optimal performance of your boat and safeguards the engine. Additionally, remember to replace the air filters regularly. Much like a vacuum cleaner’s bag, an air filter can become full. If it becomes too clogged, it will no longer function effectively. The frequency of change depends on how often you use your boat and the environments you navigate. If unsure, consulting a professional is advisable. Maintaining your boat’s air filter is straightforward. Regular inspections to check for dirt and timely replacements are generally all that’s required. By keeping the air filter clean, you…

- Boat Battery

Boat Batteries Batteries are one of the most important components in a boat. They supply the power needed to start and run the engine, operate electronic devices, and keep navigation systems functional. Like a car, a boat depends on its battery for smooth operation. Which is why we offer a wide range of high-quality marine batteries specifically designed for challenging sea conditions. Our reliable, durable, and long-lasting batteries ensure your boat is always prepared for the water. Read MoreWe stock Mastervolt Batteries, a top brand among boaters; known for their exceptional performance. Our selection includes 12V 55Ah to 12V 225Ah, suitable for various boat sizes and needs. Additionally, we offer Mastervolt Chargemaster battery chargers designed to charge and maintain your battery’s health. If you’re in need of a battery selector switch, we’ve got you covered. Whatever you need, we have it. From upgrading to replacing your boat’s battery, Boat Hut is your one-stop-shop for all your marine battery needs.

- Bung

Boat Bung When discussing boating, there’s a small component often overlooked, yet essential for keeping your boat afloat—the boat bung. This small plug fits into a hole at the bottom of your boat, primarily to prevent water from entering while you’re on the water. Think of the bung as similar to a bathtub plug. Just as you insert the plug to stop water from draining out of your bath, you insert the bung in your boat to keep water out. Once you’re finished boating and pull your boat out of the water, you remove the bung to let any water that has accumulated inside drain away. Read More Boat bungs are typically made from durable materials like rubber or plastic, which are chosen for their strength and ability to withstand water pressure without leaking. They must fit perfectly to ensure no water seeps through. It’s crucial to check your boat’s bung before heading out to ensure it’s securely in place and not damaged. A missing or faulty bung can lead to water filling up inside your boat, which could be dangerous. It’s also wise to keep a spare bung on board, just in case…

- Cable

Boat Cables A boat cable is a robust wire or rope that performs many tasks on a boat. Different types of cables are used for different purposes. For example, some cables are designed for steering the boat, while others may be used to hoist sails or anchors. These cables need to be exceptionally strong as they often pull heavy loads and must operate smoothly to ensure the boat functions properly. Read More One key type of cable on a boat is the steering cable. Similar to turning the handlebars on a bicycle to change direction, the person piloting the boat uses the steering wheel to move the steering cable, which in turn directs the boat through the water. Another type of cable you might find on a boat is used for the electrical systems. These electrical cables transport power from the boat’s battery to various components such as lights, radios, and sometimes even a refrigerator. They must be specially manufactured to be safe around water, which conducts electricity and can pose a risk. When selecting a cable for a boat, it’s crucial to choose the right type for the specific task it needs to…

- Hose

Maintaining your boat is important, and choosing the right hoses and components is key to keeping it running well in marine environments. We offer a wide range of hoses and accessories to meet all your boating needs. Our selection includes: Read More Water Hoses: These are essential for applications involving potable water, washdowns, and general deck water. Water hoses must be flexible yet robust enough to handle varying pressures and temperatures. Materials such as reinforced rubber or PVC are commonly used due to their durability and resistance to kinks. Bilge Hoses: Designed for bilge pump discharge systems, these hoses require exceptional flexibility and kink resistance to ensure efficient water drainage from the bilge. Typically constructed from reinforced PVC or rubber, they are designed to withstand the harsh environment below decks and prevent blockages or restrictions in flow. Sanitation Hoses: Sanitation hoses are critical in plumbing applications, particularly in waste management systems on board. They must resist odours and prolonged exposure to liquids without degrading. Common materials for these hoses include EPDM, PVC, or polyurethane, each providing resistance to odour permeation and the various chemicals found in waste systems. Exhaust Hoses: These handle the hot…

- Strainer