Description

Our Advantages

Smooth, Durable, High Precision Overall Performance

All SOLAS propellers are developed by a state of art process. Through a sequence of theoretical calculations, geometry design, prototype testing, pilot production and field tests, SOLAS propellers are designed to meet customers’ various requirements. Modern CAD, CAM and CAE technologies are used to ensure that high precision tools are used for products.

Unparalleled Durability

SOLAS Stainless Steel Propellers – Feature the industry’s highest percentage of chromium, nickel, and molybdenum. Our material resists rust from salt water and increases the stability of the propeller blades.

SOLAS Stainless Steel propellers are made by investment casting process.

SOLAS focuses its production improvement efforts on efficient use of space, increased yield, first in first out processes and automated equipment (such as robotic dipping arms). We are constantly improving processes and striving even higher. Performance and durability are the characteristics of the SOLAS stainless steel products.

This is a generic listing for all stainless Steel Solas Propellers

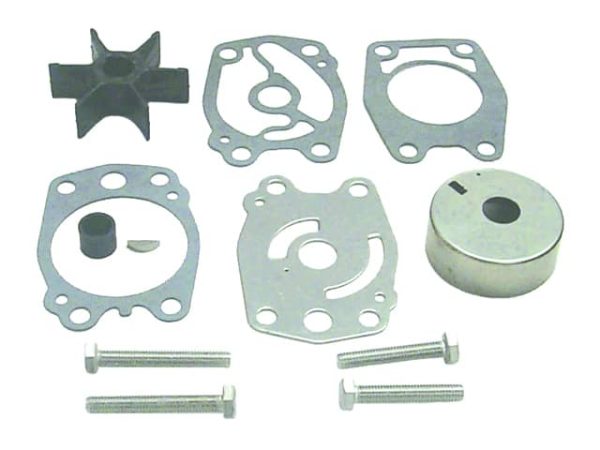

We are able to source a variety of sizes, pitches and hub kits.

Your price will include a hub kit to suit your make of outboard or engine.

We can arrange an individual quote based on your performance needs and craft details.

Reviews

There are no reviews yet.