Boat engines involve various parts that work together to keep the vessel running smoothly. One important part is the boat impeller – a small but mighty component that plays a vital role in the engine’s functioning. A boat impeller is a small, rotating device found inside an engine’s water pump. Its function is to move water through the engine’s cooling system to prevent it from overheating. In this blog, we’ll discuss how boat impellers work, the different types of impellers available, signs of damage or wear, and tips for proper maintenance to ensure that your boat’s impeller continues operating at its best capacity. If you want to learn more about boat impellers check out the impellers category on Boat Hut.

How Boat Impellers Work

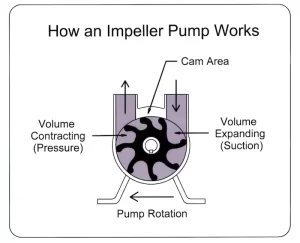

Image source: GlobalSpec

An impeller is a small, rotating component that forces water through a specific channel in the engine. The impeller helps the engine stay cool by pushing fresh water in and pumping out heated water. The impeller’s rotation creates a suction that brings water into the pump, and the fins propel it around the engine block. The impeller blades rotate at high speeds, turning water into a high-pressure, high-velocity stream that keeps the engine cool.

Types of Boat Impellers

Boat impellers are typically made of neoprene for pumping water-based fluids, or nitrile if oil-based fluids are present.

Flexible Rubber Impellers

Flexible rubber impellers are the most common types of impellers you’ll find in a lot of small to medium-sized boats. The majority of flexible impellers are made of neoprene and nitrile, designed to rotate freely and maintain a perfect seal, thus minimising the chances of water leaks. Rubber impellers come in different shafts and different types of rubber, making them suitable for different pump applications. They are also cost-effective, easy to replace, and require minimal maintenance compared to other impeller types.

Composite Impellers

Composite impellers, as the name suggests, are designed using composite materials such as carbon fibres, polyester, and ceramics. Although not as common as flexible impellers, they have excellent resistance to corrosion and abrasion, making them more durable than other impeller types. Composite impellers are also designed to reduce cavitation and generate less heat than other impeller types. However, they are relatively expensive and may only suit some boat models.

Stainless Steel Impellers

Stainless steel impellers are designed for high-performance boats that require a lot of horsepower, making them rare for the average vessel. They are robust, corrosion-resistant, and durable, making them popular for offshore speed boats and high-performance yachts. Stainless steel impellers are also designed with a unique design and blade shape that generates more water for maximum cooling efficiency.

Differences Between Various Impeller Types

The primary differences between the boat impellers are the materials used, their shapes, and their application. Each impeller is designed to suit specific engine models, water conditions, and boat types. While rubber impellers are ideal for small to medium-sized boats, other impeller types, such as stainless steel and composite impellers, are ideal for high-performance boats and challenging water conditions. If you’re looking to replace your impeller, make sure you know the existing part number for a quick replacement. You can also consult a manufacturer to determine the best impeller for your boat.

Signs of a Damaged or Worn-Out Boat Impeller

Overheating Engine

An overheating engine is often a clear sign of a worn-out or damaged boat impeller. The impeller plays a crucial role in the engine’s cooling system. If it’s damaged, it won’t be able to pump enough water for cooling, causing the engine to overheat.

Unusual Noises from the Water Pump

Unusual noises from the water pump can indicate a damaged impeller. Listen for any grinding or rattling sounds. These could be caused by a broken impeller blade, which would disrupt the normal operation of the water pump.

Checking the Impeller for Visible Damage

Regular checks of the impeller can reveal visible signs of damage. These may include chipped, bent, worn, or missing blades. Any visible damage to the impeller is a clear sign that it needs to be replaced.

Importance of Regular Impeller Maintenance

Regular maintenance is key to ensuring that your boat’s impeller runs efficiently. We recommend checking your impeller after 100 hours of operation or each year, whatever comes first. More frequently if you use your boat often or in harsh conditions. Proper maintenance helps extend the impeller’s lifespan, prevent engine damage and overheating, and save on replacement costs.

Tips for Maintaining Your Boat Impeller

Flushing the cooling system after each use and storing your boat correctly are excellent practices to keep your impeller running smoothly. After each use:

- Flush the cooling system thoroughly with fresh water to eliminate salt, debris, or contaminants, prolonging the impeller’s life.

- Store your boat in a dry and cool place to protect the impeller from any wear, tear, or damage while it’s not in use.

Frequently Asked Questions (FAQs) About Boat Impellers

How long do boat impellers typically last?

The life expectancy of a boat impeller varies depending on the type of material and usage. Generally, an impeller made out of rubber should last about one year, while an impeller made out of plastic or metal may last up to five years with proper maintenance.

Can I replace the impeller or do I need a professional?

Replacing an impeller yourself can be easier than it seems. If you’re unsure where to start, speak with the Boat Hut team and your boat manufacturer to guide you through the process and provide you with some helpful tips.

Is it normal for the impeller to wear out over time?

It is normal for boat impellers to wear out over time due to usage and age. With proper maintenance and care, however, you can extend the life of your impeller and avoid costly replacement costs. The more frequently you use your boat, the more often you should check the condition of the impeller. Doing so can help ensure you get the most out of your impeller.

How to identify the correct replacement impeller for my boat?

To determine the correct replacement impeller for your boat, you should check the model number of your engine. The model number will help identify which type and size of impeller you need. You can also speak with the knowledgeable Boat Hut team to ensure you choose the right impeller for your boat.

Conclusion

In conclusion, boat impellers are crucial to your engine’s water pump. Maintaining and checking your boat impeller regularly can help prevent expensive repairs, replacements, damage, overheating and ensure that your boat runs smoothly. By incorporating the tips and guidelines discussed in this blog, you’ll have an easier time maintaining your impeller’s efficiency and extending its lifespan. Remember to always take care of your boat engines and impellers, so keep your impeller well-maintained and enjoy smooth sailing for many years.